In the era of rapid advancement in drone technology, whether for high-definition aerial surveying and mapping, precision agricultural plant protection, or emergency supply delivery and complex environmental monitoring, drones have evolved from simple remote-controlled toys into highly intelligent aerial robots. Behind this transformation lies the flight control system's near-obsessive demand for real-time, precise attitude and motion data. The core technological cornerstone meeting this demand is the micro-electromechanical system (MEMS) inertial sensor—acting as the drone's "inner ear" and "balance nerves," silently sensing every moment of attitude change and motion state. These sensors serve as the physical foundation enabling drones to achieve stable hovering, autonomous navigation, agile maneuvering, and precise control.

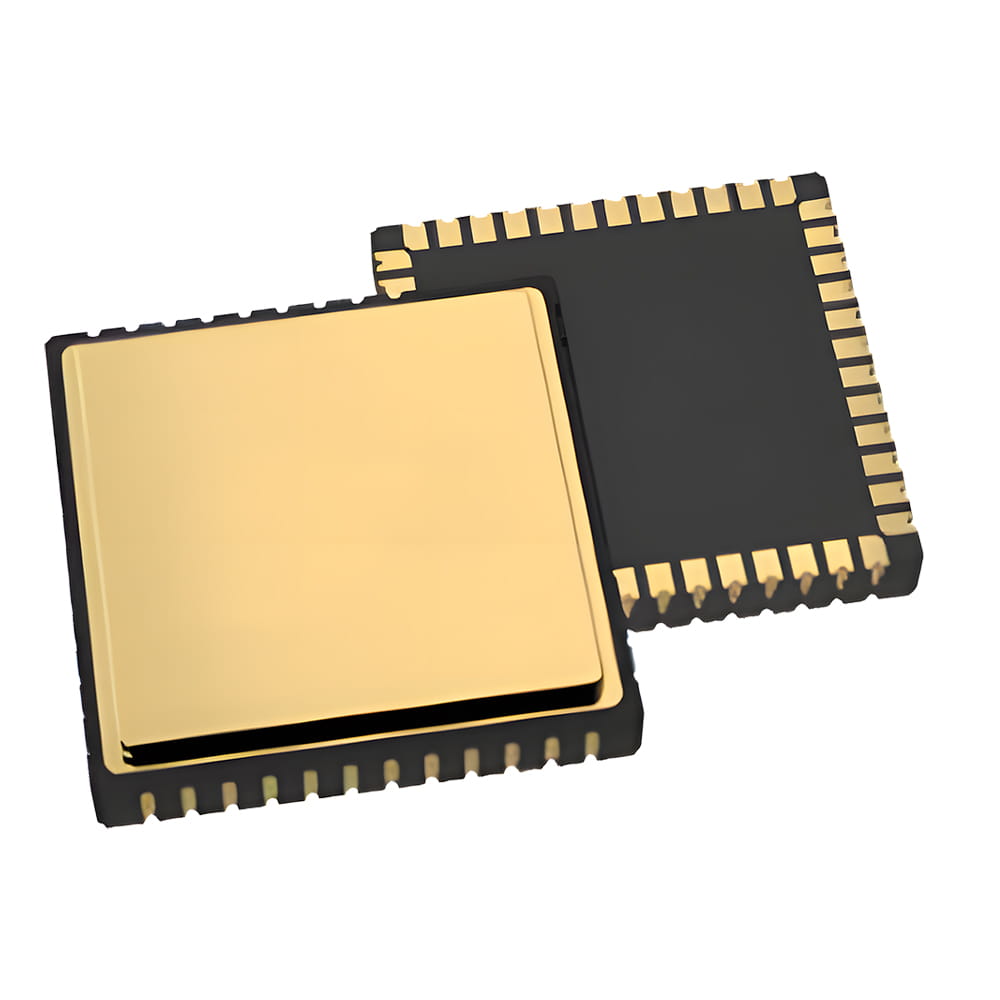

Traditional high-precision inertial navigation systems rely on bulky, expensive, and power-hungry optical or mechanical gyroscopes and accelerometers, severely limiting their application in consumer-grade and industrial-grade drones that prioritize lightweight, low cost, and long endurance. The groundbreaking advancements in MEMS technology have completely transformed this landscape. By seamlessly integrating micro-scale mechanical sensing structures with integrated circuit processes, it has miniaturized inertial sensors to the chip level. For instance, the ACM-1700 series of high-performance MEMS single-axis accelerometers from Micro-Magic employ advanced MEMS processes, achieving a wide range from ±10g to ±200g, a bandwidth up to 100Hz, and exceptional bias stability (down to 50μg) within a compact package measuring just 7.8 x 5.8 x 3mm. With robust construction capable of withstanding impacts up to 10,000g and full-temperature-range compensation via integrated temperature sensors, the ACM-1700 series ensures reliability and measurement consistency during drone's aggressive maneuvers and in complex environments. Whether monitoring linear acceleration or deceleration of drones or detecting vibrations caused by wind or maneuvers, the ACM-1700 series delivers precise data inputs.

ACM-1700

| Measuring Range | ±10~30/±30~50/±70~100/±150~200g |

| Measuring Axis | X |

| Zero Bias Stability (10s, 1σ) | 50/100/200/500μg |

| Zero Bias Temperature Coefficient (full temperature) | 50/50/100/200μg/℃ |

| Impact Resistance | 10000g,2ms,1/2 sine |

| Vibration Rectification Error (6grms) | 0.4/0.15/0.05mg |

| Communication Protocol | I2C/SPI/UART |

| Output Signal | Digital |

| Pack and Size | Chip, 7.8*5.8*3mm |

| Weight | 1.5g |

However, perceiving only linear acceleration is insufficient to fully describe a drone's motion state. Rotational motion, specifically angular velocity around three axes, is equally crucial for attitude determination. The MG-XXXX series high-precision MEMS single-axis gyroscope by Micro-Magic is precisely designed for this purpose. This series employs an innovative MEMS structure capable of accurately measuring angular velocity along the rotation axis perpendicular to the chip surface. Its high performance is characterized by extremely low noise and exceptional bias stability, providing precise angular velocity feedback for drone flight control. Through its flexible SPI digital interface and configurable registers (such as adjusting output bandwidth from 12.5Hz to 800Hz or setting data update rates from 62.5Hz to 2000Hz), the flight control system can optimize sensor response for different flight modes (e.g., smooth cruising or agile maneuvers), achieving the best balance between suppressing high-frequency noise and maintaining rapid signal response. The combination of the MG-XX series and the ACM-1700 series forms the fundamental sensing pair for drones to perceive their three-dimensional spatial motion in principle.

However, integrating multiple independent, high-performance MEMS sensor chips (three-axis gyroscope + three-axis accelerometer) into drone flight control and processing their raw data to obtain stable and usable attitude information is a complex engineering challenge involving precision calibration, temperature compensation, sensor fusion algorithms, and high-speed data processing. This is precisely where the value of MEMS inertial measurement modules such as U503, U4930, U16575. It is not a simple sensor stack, but a highly integrated and intelligent solution. This type of IMU module is housed in a sturdy aluminum alloy casing and has achieved precise positioning and installation of three-axis MEMS gyroscopes and three-axis MEMS accelerometers, integrating high-performance microprocessors.

Taking U4930 IMU module as an example, its core progressiveness lies in the full temperature calibration and system level compensation completed before delivery. The processor inside the module not only synchronously collects raw data from six axes at high speed (up to 2000Hz), but more importantly, it applies a pre calibrated compensation parameter matrix over a wide temperature range (-40℃ to +85℃) to perform real-time digital compensation for dozens of error terms such as zero bias error, scale factor nonlinearity, non orthogonal error, and acceleration sensitivity (g-sensitivity) of the gyroscope for each sensor. This allows the module to directly output high-precision angular velocity (°/s) and acceleration (m/s ²) data after temperature calibration and error correction. Users no longer need to perform tedious laboratory level calibration, greatly simplifying system integration and ensuring consistency and reliability of performance under different climate conditions. The RS422 interface it provides can stably output data packets containing angular velocity, acceleration, internal temperature, and high-precision timestamps at a frequency of up to 200Hz. It can also output TOV differential pulse signals that are strictly synchronized with data sampling, facilitating precise time alignment with external systems such as GPS, which is crucial for integrated navigation.

In actual drone flight, these clean inertial data from IMU modules are fed in real-time into the core of flight control - attitude calculation and navigation algorithms (usually based on Kalman filters). The algorithm intelligently integrates the specific force information measured by the accelerometer (used to determine the direction of gravity, i.e. pitch and roll angles) with the angular velocity information measured by the gyroscope (used to integrate and obtain attitude changes). Through this' sensor fusion ', the system is able to overcome the respective shortcomings of accelerometers being susceptible to vibration interference during dynamic maneuvers and gyroscope integration drifting over time, thereby outputting stable, accurate, and error free real-time three-dimensional attitude (pitch, roll, yaw), angular velocity, and linear acceleration information. These pieces of information are the foundation of closed-loop control in flight control: the flight control compares the target waypoint or remote control instructions with the current real-time attitude and position, calculates the precise thrust commands of each motor, and drives the drone to complete a series of complex actions such as hovering, climbing, turning, obstacle avoidance, etc.

Therefore, from the basic physical quantity perception provided by the chip level ACM-1700 accelerometer and MG-XXXX gyroscope, to the integrated, calibrated, and intelligent data supply achieved by the module level U503, U4930, U16575 inertial measurement units, MEMS inertial sensor technology constitutes a complete technology stack, gradually solving the problem of UAV attitude perception layer by layer. They enable modern drones not only to 'fly', but also to 'fly steadily', 'fly accurately', and 'fly intelligently'. With the improvement of autonomous driving levels and the increase in task complexity, the requirements for the performance of MEMS inertial sensors will also rise. The continuously evolving high-performance and highly integrated MEMS solutions are undoubtedly the indispensable underlying support for future unmanned aerial vehicles to move towards full autonomy, clustering, and intelligence.

Xml Privacy Policy Blog Sitemap

copyright @ Micro-Magic Inc All Rights Reserved.

Network Supported

Network Supported